Jan 18, 2013 · Restore the atmospheric pressure and leave the vials immersed for 30 minutes. Rinse the outside of the vials. None of the vials contains any trace of coloured solution. 4.Extractive test: In this test, the closure is boiled with water for four hours under reflux and the water evaporated to dryness. The residue must not exceed the specified

Mar 6, 2021 · Even small leakages may reduce the shelf life of products due to changes in the composition of headspace gases and moisture content. In this respect, developing better sealing techniques to maintain product quality has become a very important target for food industry. 5. In packaging design, there are three different aspects related to sealing.

Headspace Sampling for GC – The Basics. Headspace sampling is a type of sample introduction technique for gas chromatography (GC) and gas chromatography-mass spectrometry (GC/MS). For headspace techniques, the gas layer, or the headspace above the sample in a vial, is analyzed as opposed to withdrawing a volume from within the sample layer

Despite introducing modern analytical technology to assess blend uniformity, many companies are still using traditional blend sampling thieves and wet chemistry to assess blend homogeneity. The use of statistically based sampling plans allows variance component analysis to be conducted on both blend and dosage unit data. This article shows how various combinations of blend and dosage unit

This article (1) illustrates several different types of analytical errors and situations within laboratories that may result in increased variability in data, (2) provides recommendations regarding prevention of testing errors and techniques to control variation, and (3) provides a list of references that describe and advise how to deal with

Jan 1, 2019 · Errors can occur in all the steps in the laboratory testing process, and such errors can be classified as follows (see Table 1.1 ): 1. Pre-analytical steps, encompassing the decision to test, transmission of the order to the laboratory for analysis, patient preparation and identification, sample collection, and specimen processing. 2.

Jan 5, 2022 · 1. Introduction. Process Analytical Technology (PAT) was defined by the Food and Drug Administration guidance “PAT- A Framework for Innovative Pharmaceutical Development, Manufacturing and Quality Assurance” [1] as a mechanism to design, analyze, and control pharmaceutical manufacturing process through the measurement of Critical Process Parameters (CPP) with Critical Quality Attributes

Purge pump at high flow rate (e.g., 5-10 mL/min.), prime system if necessary. (Prime each pump head separately.) If system has check valve, loosen valve to allow air to escape. If problem persists, flush system with 100% methanol or isopropanol. If problem still persists, contact system manufacturer.

Based on the dimensions in ISO 8362, 13mm 2R, 3R, and 4R vials have between 1.1 and 1.4mm of available space to crimp aluminum onto, while 20mm 6R, 8R, 10R, and 15R vials have between 1.6 and 1.9mm. Exceeding the available neck to crown distance results in crimping onto the neck, which typically manifests as a fold in the metal near the neck.

Overall, despite the inherent variability of RSF, this study shows that it is a feasible parameter for capping process quantification and demonstrates the potential of RSF measurement in capper setup.

Mar 1, 1998 · Analytical variability is a generally recognized concept in the analysis of chemical goods 1, 2, including pharmaceutical products 3, 4, 5. Identifying the sources of analytical variability and the magnitude of the variability is critical in the establishment of product specifications.

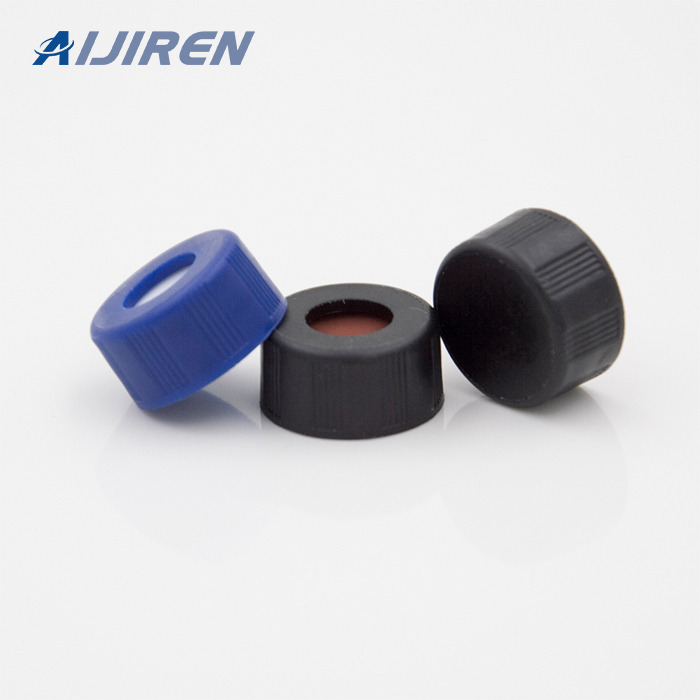

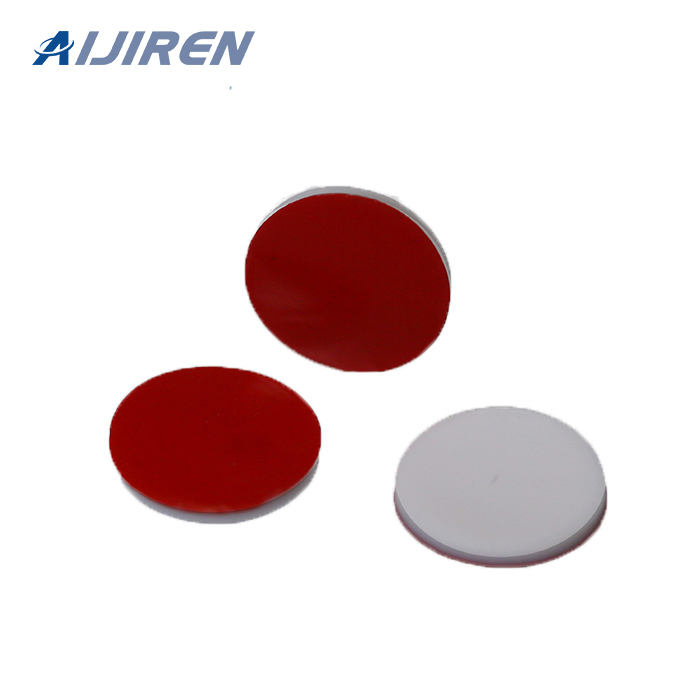

extruded from its proper position between the vial rim and cap further compromising vial sealing. In the current experiments a new type of vial and closure were evaluated for sealing under normal and attempted over tightened positions. Sealing of a chromatography vial is dependent on maintaining the correct amount of

A vial container closure system for pharmaceutical, biological, cell, and gene therapies must maintain container closure integrity to ensure that the drug products remain stable and free of contamination from microbial ingress.

Sep 1, 2017 · Modern and flexible technologies such as robotics help to streamline the integration of RTU vials into aseptic fill/finish processes. This article discusses how one such process that benefits from robotic automation is the vial sealing or capping process required to fully close vials. Integrating Ready-To-Use Vials with Proven Sealing Solutions

Jun 21, 2021 · Interfacing manufacturing processes with analytical techniques is essential in PAT, as it facilitates process development according to QbD principles and enables real-time release testing (RTRT) . PAT is applied to each unit operation in the manufacturing process; CPPs, which have a significant influence on CQAs, are controlled to present a